H-20 (Ground Floor), Pocket-F, Sector-1,

Bawana (DSIDC), New Delhi - 110039, India

Paving Mix Tests,Marshall Stability

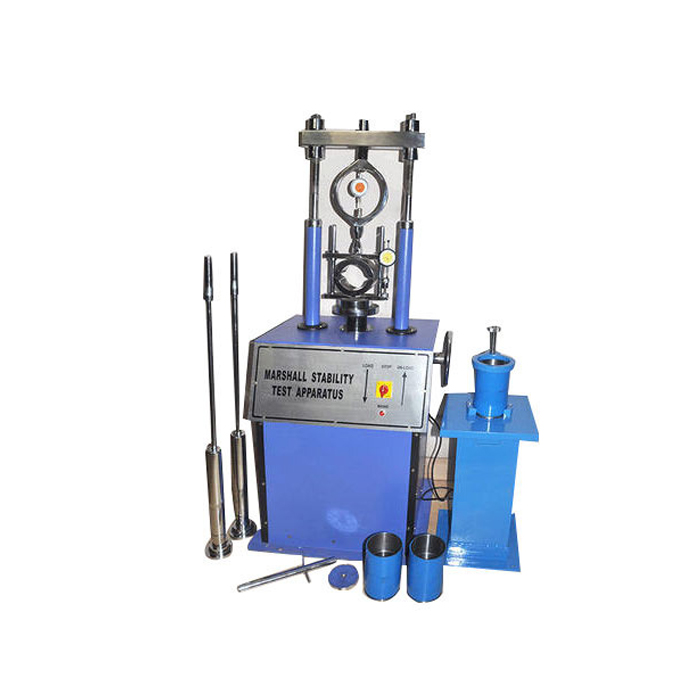

Marshall Stability Test Apparatus

ASTM: D 1559 T- 62. BS 598-107

Marshall Apparatus Consists Of:

Features

Marshall Apparatus Consists Of:

Features

- Robust construction

- 50KN capacity

- Rate of travel 50.8mm/min

- Safety cut-off switch

Automatic Marshall Stability Test Machine

A. Automatic Marshall Stability Test Machine, 50 KN, 220-240 V 50-60 HZ

B. Breaking Head (Stability Mould) 4"

C. Linear Potentiometric, Displacement Transducer, 25x0.001 mm with Bracket for A and B

D. Indirect Tensile Splitting Device for Compacted Bituminous Samples 100 mm (4") Dia.

EN 12697-34, 12697-23, 12967-12, ASTM D1559, D5581, D 6927; AASHTO T245

The 50 kN capacity Automatic Marshall Stability Test Machine is used to determine the maximum load and flow values of bituminous mixtures. The machine comprises of a robust and compact two column frame with adjustable upper cross beam. The unit is a bench mounting compression frame with motor and worm gear housed within the base unit. The speed of the lower platen can be adjusted between 6 mm/min to 60 mm/min using the data acquisition and control unit. For safety, the up and down travel of the lower platen is limited the use of limit switches. Rapid adjustment of the platen is controlled using the up and down buttons on the front panel of the machine. The machine can be hand operated by a lateral hand wheel for calibration purposes.

The measuring system consists of a 50 kn capacity strain gauge load cell fitted to the upper cross beam to read stability values and the 25 x 0.001 mm linear potentiometric displacement transducer fitted to the breaking head. The Automatic Marshall Stability Machine is suitable for testing 6" dia. 4" dia. specimens conforming to ASTM D5581

B. Breaking Head (Stability Mould) 4"

C. Linear Potentiometric, Displacement Transducer, 25x0.001 mm with Bracket for A and B

D. Indirect Tensile Splitting Device for Compacted Bituminous Samples 100 mm (4") Dia.

EN 12697-34, 12697-23, 12967-12, ASTM D1559, D5581, D 6927; AASHTO T245

The 50 kN capacity Automatic Marshall Stability Test Machine is used to determine the maximum load and flow values of bituminous mixtures. The machine comprises of a robust and compact two column frame with adjustable upper cross beam. The unit is a bench mounting compression frame with motor and worm gear housed within the base unit. The speed of the lower platen can be adjusted between 6 mm/min to 60 mm/min using the data acquisition and control unit. For safety, the up and down travel of the lower platen is limited the use of limit switches. Rapid adjustment of the platen is controlled using the up and down buttons on the front panel of the machine. The machine can be hand operated by a lateral hand wheel for calibration purposes.

The measuring system consists of a 50 kn capacity strain gauge load cell fitted to the upper cross beam to read stability values and the 25 x 0.001 mm linear potentiometric displacement transducer fitted to the breaking head. The Automatic Marshall Stability Machine is suitable for testing 6" dia. 4" dia. specimens conforming to ASTM D5581

Mixer With Heating Jacket

A 6-litre Mixer Used in conjunction with an Iso Mantle, is suitable for mixing samples of asphalt.

Bench mounting Mixer, 6 liter nominal capacity. Supplied with bowl, beater and whisk. Motorised with two speed operated on 230 V A.C., Single Phase.